traction

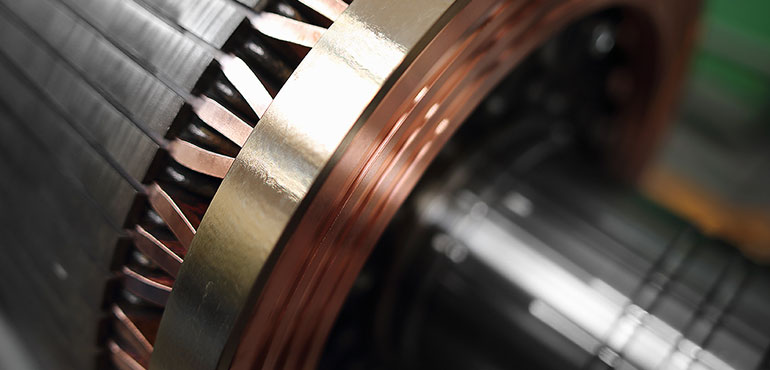

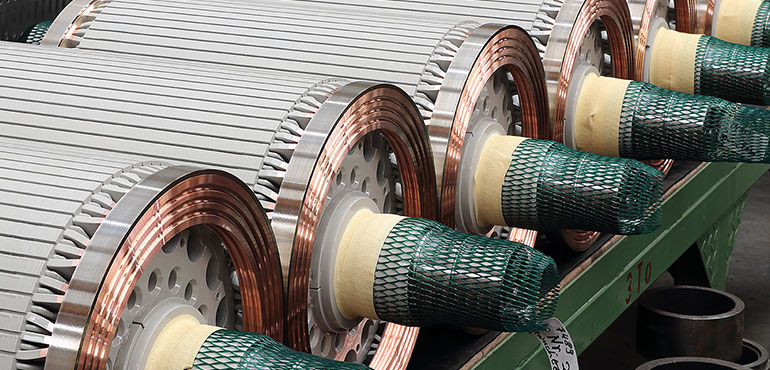

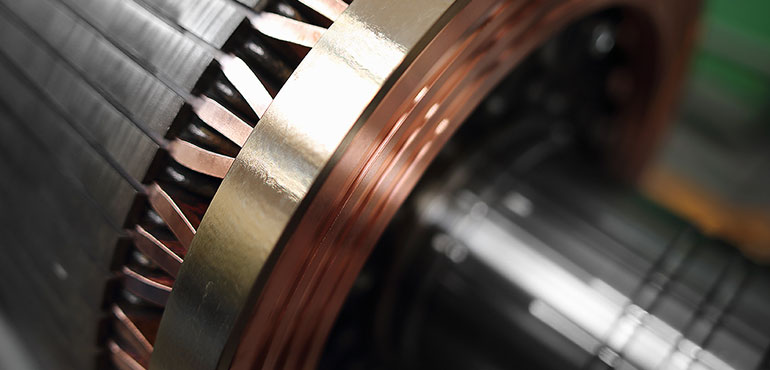

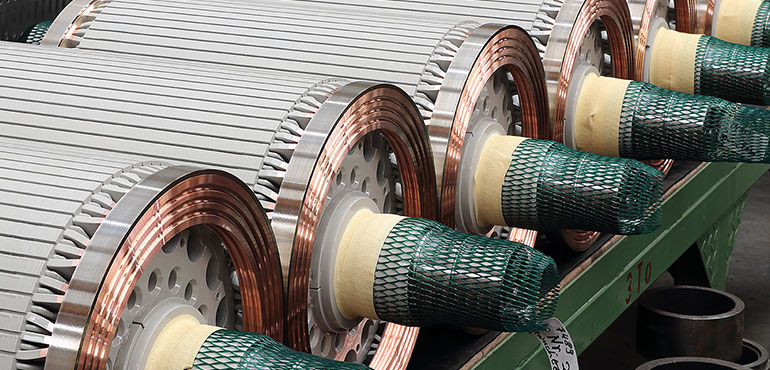

AMServ has been carrying out overhauls and repairs for over 45 years in close cooperation with the German railways (Deutsche Bahn), municipal utilities, private railways and operators of tram routes independently of manufacturers for traction motors and components thereof.

As a result of shorter cycle times and increasing speeds, the demands made of drive motors are becoming increasingly challenging. We have developed methods and techniques for refurbishing and improving these machines and therefore extending the service life. In the field of optimising high rotor speeds in regional services in particular, we were able to significantly improve the running performance and service life thanks to optimisation.

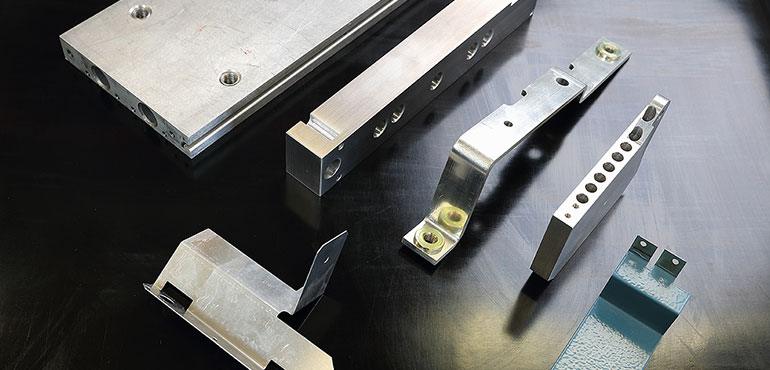

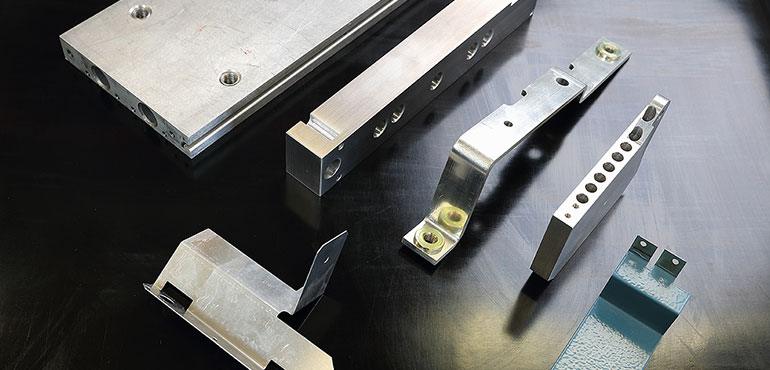

This also applies to a broad range of components, terminal buses and circuit boards in the field of frequency converter technology that we can provide as spare parts, sometimes even with improved technology. Our modern testing methods, such as partial discharge measurements and dissipation factor (tanδ) measurements, bearing current analyses, vibration and sound measurements or iron measurements with thermography of the laminated core etc. enable precise analysis and therefore ensure that our products achieve the highest quality standards.

This means that we are well prepared to provide support in the field of traction in the future too. The development of special production and testing processes guarantees the highest possible safety standards for your transport operations.

better than new – for sure

our service:

-

Rewindings for stators and rotors on traction machines

-

Re-lamination

-

Modifications to and optimisation of rotors

-

Maintenance of (even water-cooled) railway drives of all kinds

-

Supply of components, e.g. Fan motors, bearing caps, running board drives, shifting rings, contact sheets, terminal buses and bar packages for frequency converters etc.

-

Supply of coils and windings

-

Supply of spare parts

Contact

AMServ

Service for rotating

electrical machines

Deutsch

Deutsch English

English Français

Français