measurement technology and diagnostics for motors and generators

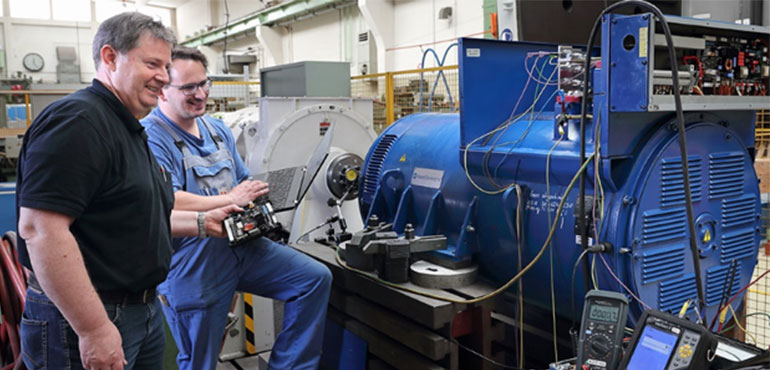

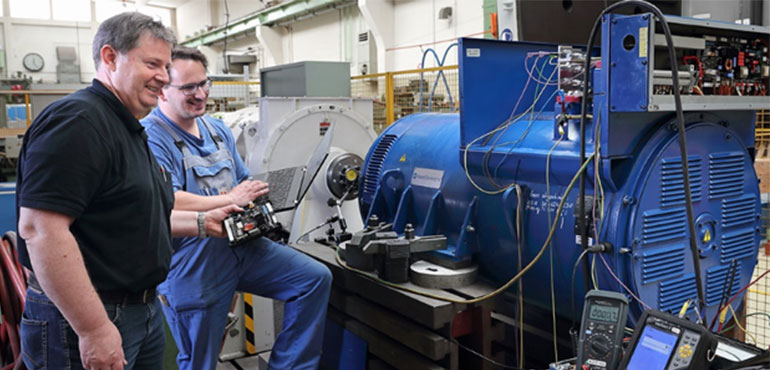

As an operator of motors and generators, you can find out more about the condition of your machines using our modern testing and diagnostic technology.

Cost-effective maintenance and the highest levels of system availability can only be achieved by using predictive diagnostics. Special measurement processes which are further developed on an ongoing basis, as well as the specialist knowledge of our employees, allow us to make conclusions about critical conditions and the necessary repair steps.

Recurring measurements and the comparison of the results ensure that we meet the prerequisites for accurate assessments. Since absolute measurement values are machine-specific, the development of several measurements over time provides an accurate picture of the condition of your machine and possible changes.

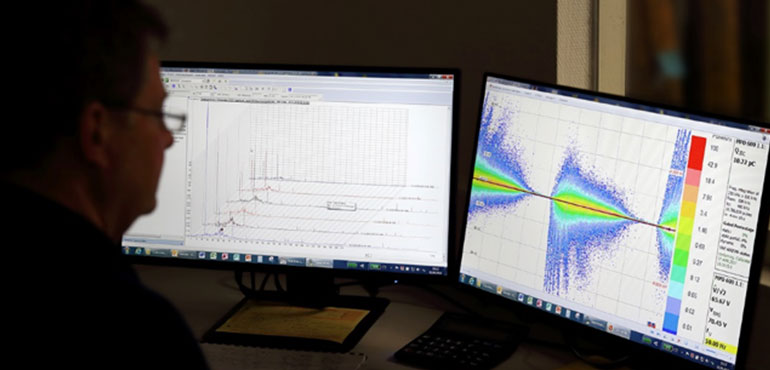

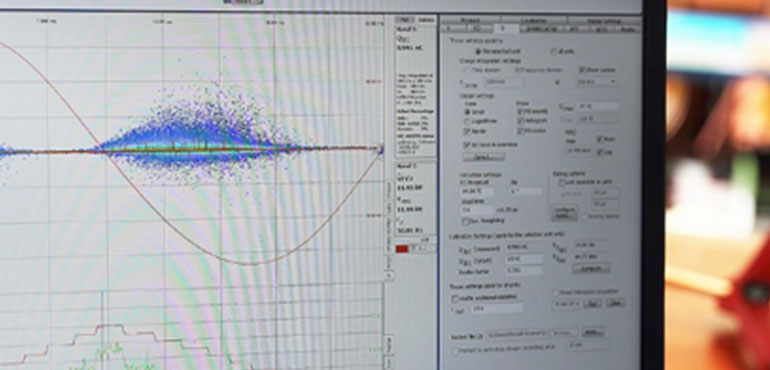

Our modern testing methods, such as partial discharge and dissipation factor measurement, as well as thermographic and endoscopic investigations, plus vibration analyses for electrical machines, help to ensure that your systems achieve the highest possible level of availability.

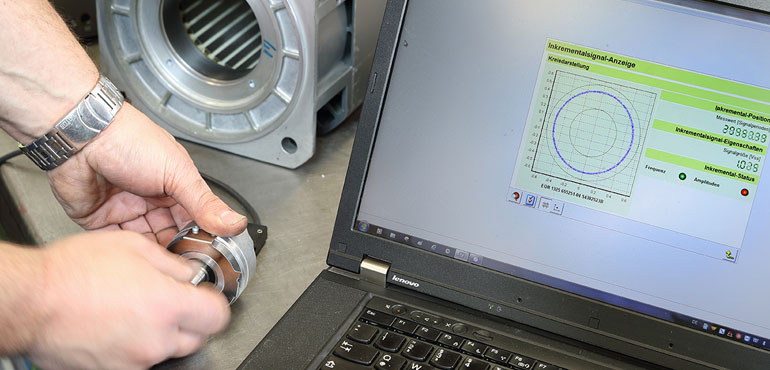

On the basis of these measurements, we can draw conclusions about the condition of the winding insulation, the quality of the alignment or the bearing.

our key areas of expertise in measurement technology and diagnostics

-

Winding resistance measurements

-

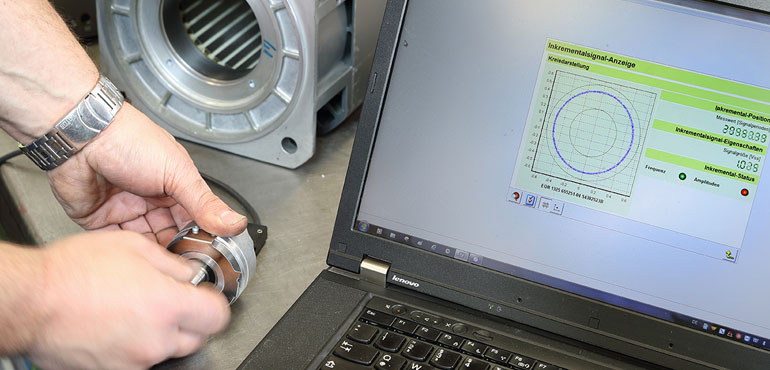

Insulation resistance measurements, including determination of the polarisation index (PI) and the dielectric absorption ratio (DAR)

-

Shorted coil tests

-

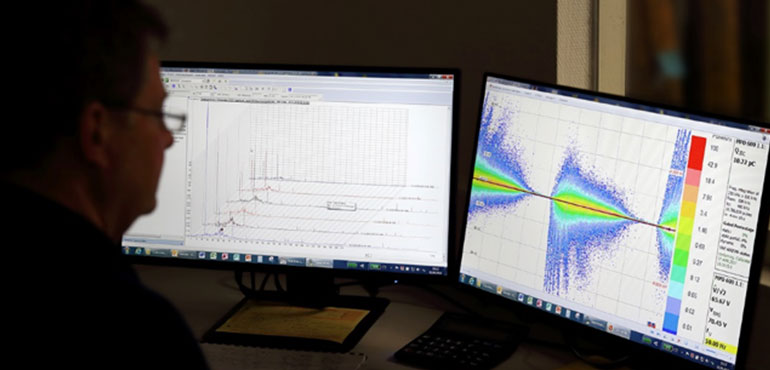

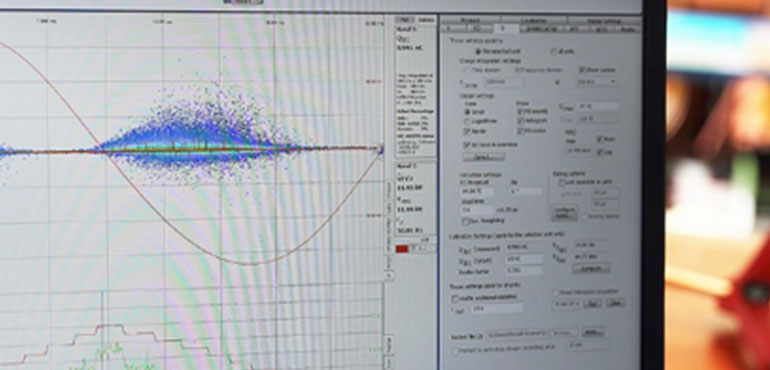

Partial discharge measurements

-

Dissipation factor measurements (loss-tangent test – tanδ

-

Measurement of bearing currents

-

Thermography

-

Endoscopic investigations

-

Vibration measurements with frequency analyses

-

Rolling bearing diagnostics

Contact

AMServ

Service for rotating

electrical machines

Deutsch

Deutsch English

English Français

Français